13 Mar Why You Should Visit Your Breakroom Operator

Bonus: Get Your Ultimate Checklist

When it comes to managing a facility, breakrooms are often overlooked — but they play a significant role in employee satisfaction, productivity, and overall workplace vibes. A great breakroom keeps employees happy, fueled, and ready to conquer the day! As a breakroom facilitator, it’s up to you to make sure your breakroom operator is on top of their game.

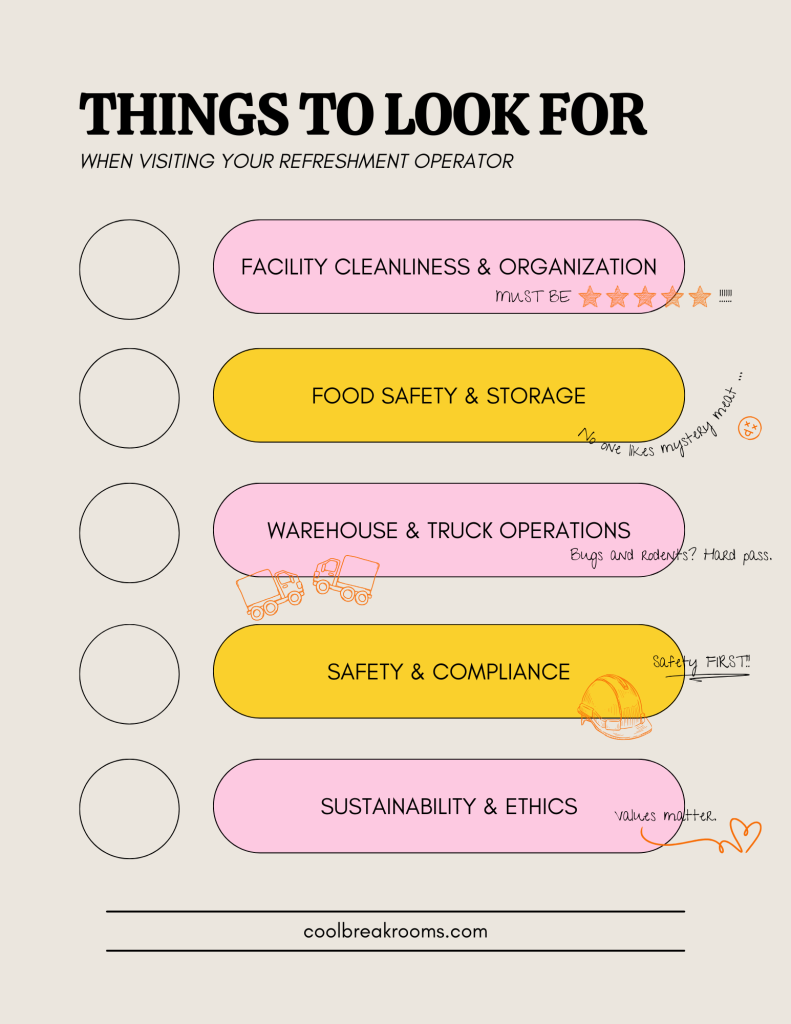

To help you find the best breakroom refreshment operator, we’ve put together the ultimate checklist — because who doesn’t love a good checklist? (Especially one that keeps your workplace running smoothly and your snacks top-notch!)

Here’s our list:

1. Facility Cleanliness & Organization: Is Your Breakroom a Five-Star Retreat?

A clean and organized breakroom sets the tone for a productive, happy workplace. Keep an eye out for:

-

- Sparkling Cleanliness – Floors, countertops, and workspaces should be fresh and tidy. If it looks like a crime scene, we’ve got problems! Dirty areas can lead to health concerns and reflect poor management.

- Stock Area Zen – Supplies should be easy to access, not buried under a pile of mystery boxes. A clutter-free space = an efficient space!

- Workflow Magic – Supplies should flow smoothly, not resemble an obstacle course. Organization helps employees grab and go without delay or distraction, which ultimately improves the employee experience.

2. Food Safety & Storage: No One Likes Mystery Meat

Keeping food fresh and safe isn’t just a rule — it’s a matter of employee health and well-being! Here’s what to check:

-

- Freshness and FIFO – “First In, First Out” isn’t just a cute acronym; it ensures fresh food is served. Products should be used in the order they were received to prevent spoilage.

- Expiration Tracking – Are items properly labeled? Expired products have no place in your breakroom! Confirm that the operator is actively monitoring expiration dates to avoid consuming expired items.

- Refrigeration – Refrigeration systems should be running smoothly, because warm yogurt = workplace disaster. Assess the type, condition, and functionality of the cooling systems used for food storage, such as refrigerators, trucks, and backup systems.

- Temperature Tracking – Operators should be monitoring food temps like a hawk. Using temperature logs and multiple thermometers to monitor food storage is a nonnegotiable. Cold chain management = fresh, safe snacks!

3. Warehouse & Truck Operations: Behind-the-Scenes MVPs

The breakroom experience starts long before the food arrives! Here’s what to check:

-

- Storage Space vs. Product Demand – Is there enough space to keep things fresh and well-stocked? Overcrowding = chaos! Chaos means ripe opportunities for operational inefficiencies.

- Inventory Turnover – Fast-moving inventory = fresh food. You want to hear them mention 17 inventory turns per year at a minimum — anything less than that means stale snacks!

- Freshness Tracking – Ask about their fresh food tracking system. No one wants a soggy sandwich past its prime. The system should effectively monitor product shelf life and ensure timely rotation.

- Smart Storage – Shelving should keep items off the floor and easy to find. Proper storage helps prevent damage to products and keeps the space organized.

4. Safety & Compliance: Keeping Things Safe & Sound

A safe breakroom is a happy breakroom! Make sure your operator is on top of:

-

- Pest Control – Bugs and rodents? Hard no. Ensure the operator has a solid pest control program in place and that regular inspections are conducted to prevent contamination.

- Safety Gear in Sight – Confirm that safety equipment like eye wash stations and fire extinguishers are strategically placed and easily accessible.

- Trained & Ready – Employees should be food safety certified. Proper training minimizes the risk of foodborne illness and workplace accidents.

- Accident Prevention – Are safety logs maintained? Proactive prevention keeps the workplace safe and shows how the operator addresses potential hazards.

5. Sustainability & Ethics:

A responsible breakroom operator invests in ethical practices. Why wouldn’t you want someone like this setting up your breakroom refreshments? Here’s how you can monitor their values:

-

- Recycling Rockstar – Are they reducing waste and recycling properly? Sustainability isn’t just trendy — it’s financially smart!

- Energy Efficiency FTW – LED lighting, efficient HVAC, and well-maintained refrigeration? An energy-efficient breakroom reduces costs and supports sustainability.

- Fair Labor Matters – Ethical labor practices mean happy employees, which translates to better service for your workplace!

- Investing in People – Does your operator care about their employees? A well-treated team delivers better results.

A Breakroom Operator Bragging About!

A breakroom operator’s attention to these details reflects their commitment to quality and service. If they cut corners on safety, organization, or employee care, they will likely cut corners on product quality and customer satisfaction. Visiting your breakroom operator and ensuring they maintain high operational standards helps guarantee a safe, clean, and efficient environment for everyone involved. Prioritizing quality, safety, and employee satisfaction leads to a better workplace and more reliable breakroom service.

By making regular visits and using this checklist, you ensure that your breakroom operator is delivering the best possible service to both your employees and your bottom line.

Now, go forth and conquer your breakroom inspection with confidence!